TAOYUAN breaks through barriers of preform mold design with advanced hot runner technology

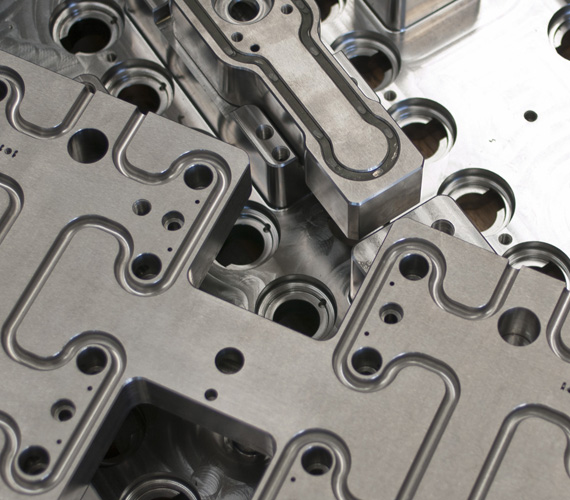

PET processing technology specialist TAOYUAN is using its advanced expertise in hot runners to create new preform molds that exploit the potential of existing injection molding machines well beyond current limits.

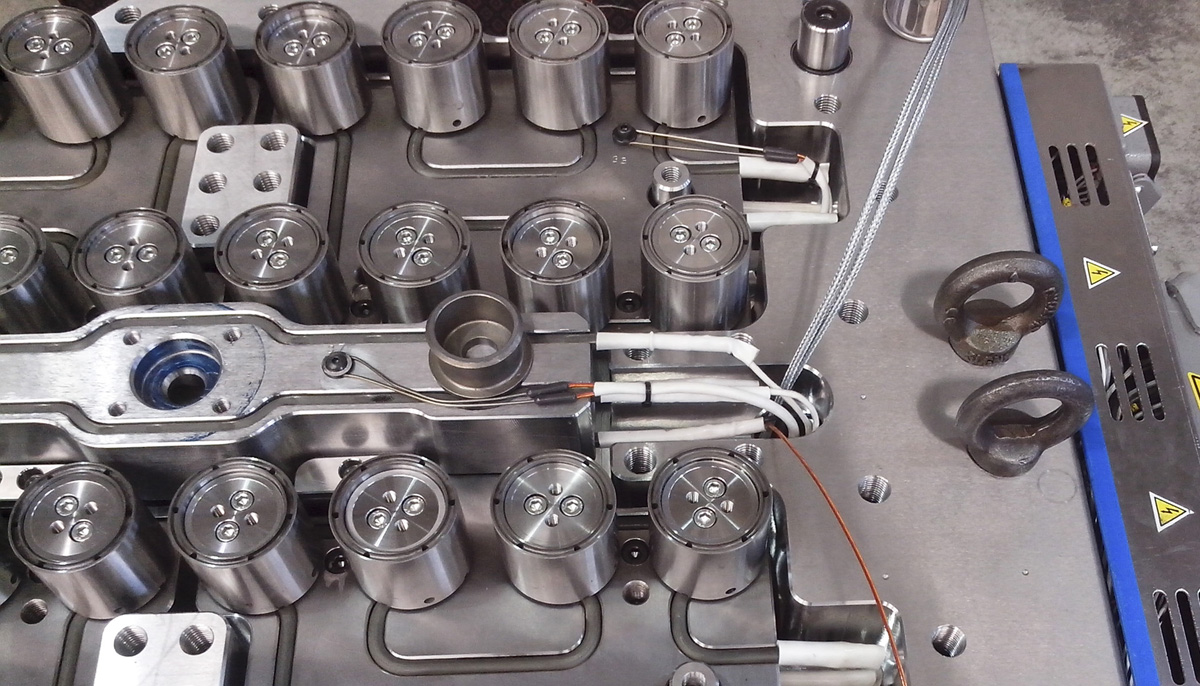

Preform producers can now use molds with non-standard cavity lay-outs to substantially raise output without putting extra stress on their machines. TAOYUAN has just produced this 180-cavity mold that fits on a regular 500-tonne machine that would normally run with molds having no more than 144 cavities – providing potential to raise productivity by 25 percent. More non-standard molds are in the pipeline, for use on smaller machines.

Users of this new tooling can chose to increase output from their 500-tonne machine, rather than running a smaller-cavitation mold at extremely fast cycle times that significantly stresses the machine, increasing maintenance costs and reducing its lifetime. TAOYUAN achieved this while taking no compromises on mold robustness: in fact, thanks to features like the SmartLock™ stack design (which delivers excellent component life), XGuidance™ (which guarantees perfect mold alignment) and its superior LongLife™ treatment, the expected life of this mold will exceed industry standards.