1,Specification of mould:

1.1 capacity: 3.5shots/ minute;

2,Material of mould:

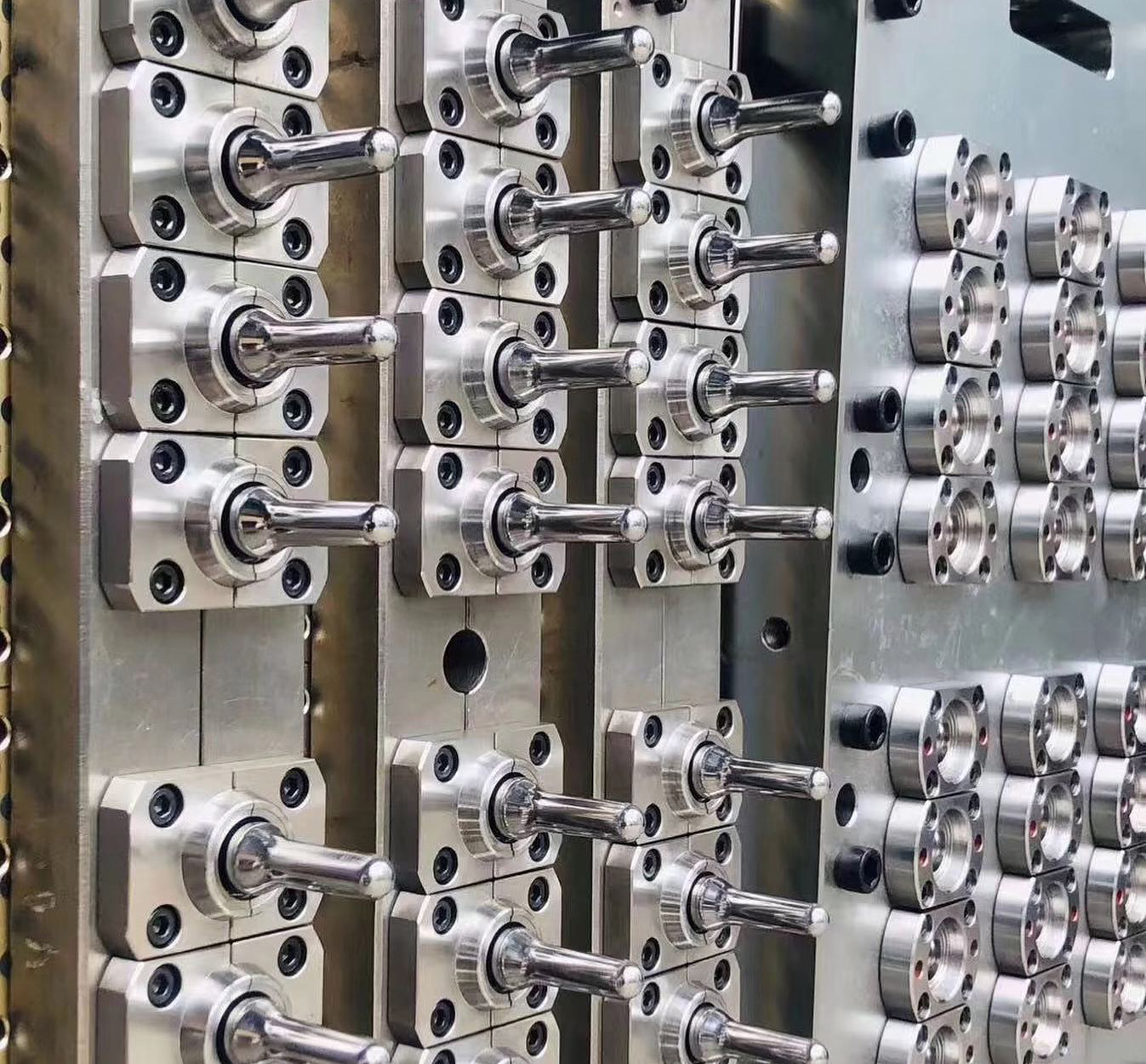

| 2.1 frame of mould | good quality imported 50# steel with Chrome on the face; (HRC:28R); |

| 2.2 Core and cavity | 2316 Stainless steel (HRC:44-46R: German); |

| 2.3 Screw: | 2316 Stainless steel (HRC:44-46R: German); |

| 2.4 Hot runner | P20 steel (HRC:28R, China); |

| 2.5 Valve | SKD61 and SKH51steel(HRC:59-61R, China); |

| 2.6 The other materials are adopted international standard parts; | |

3,Features of the mould:

3.1 Screw is made of imported nit-riding steel as the International Standard with high hardiness and long service life.

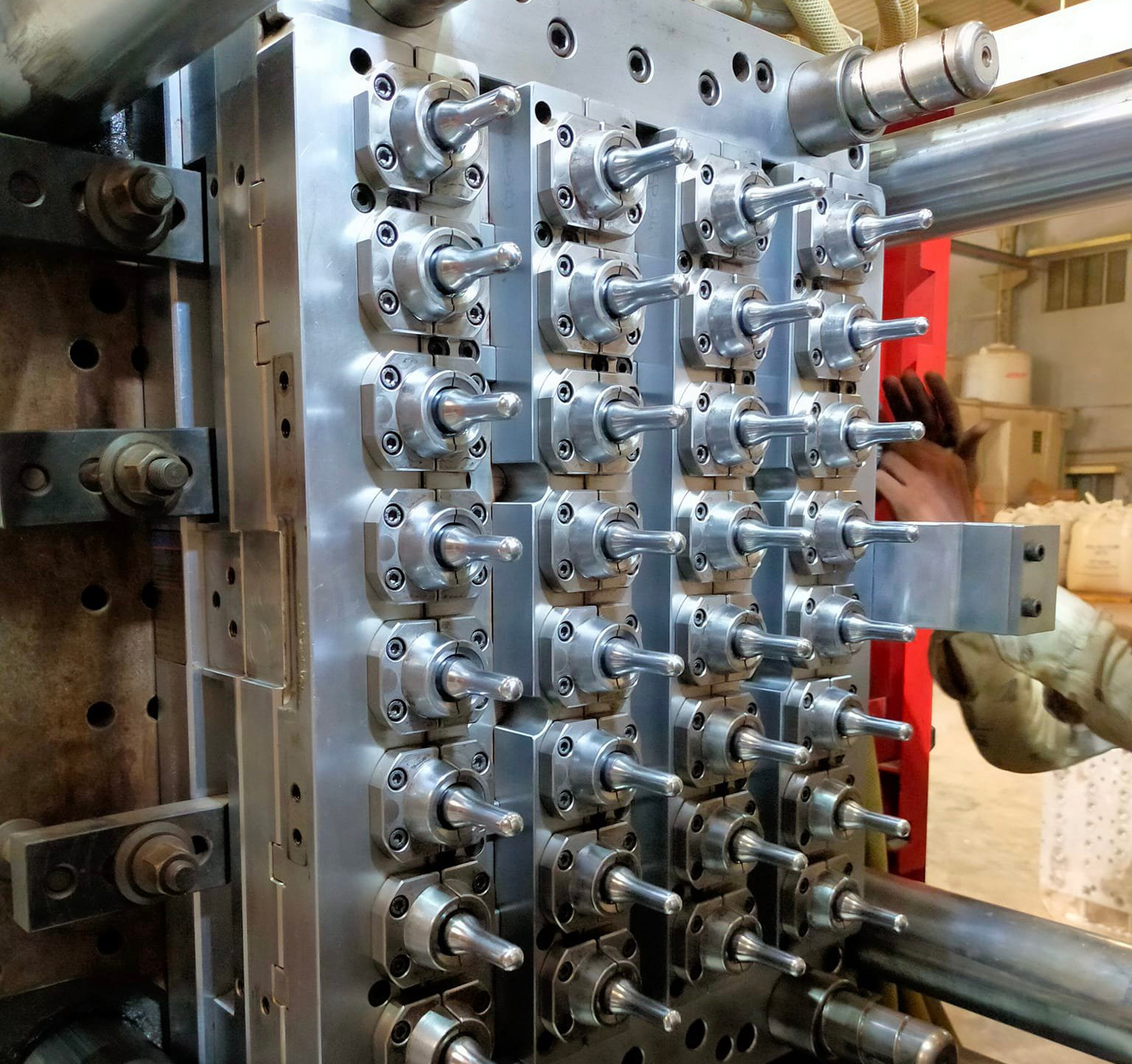

3.2 Hot runner (German HASCO), adopt best cooling system.

3.3

It can shorten the processing days, raise efficiency, improve the

quality and appearance of the products by adopts this hot runner.

3.4.

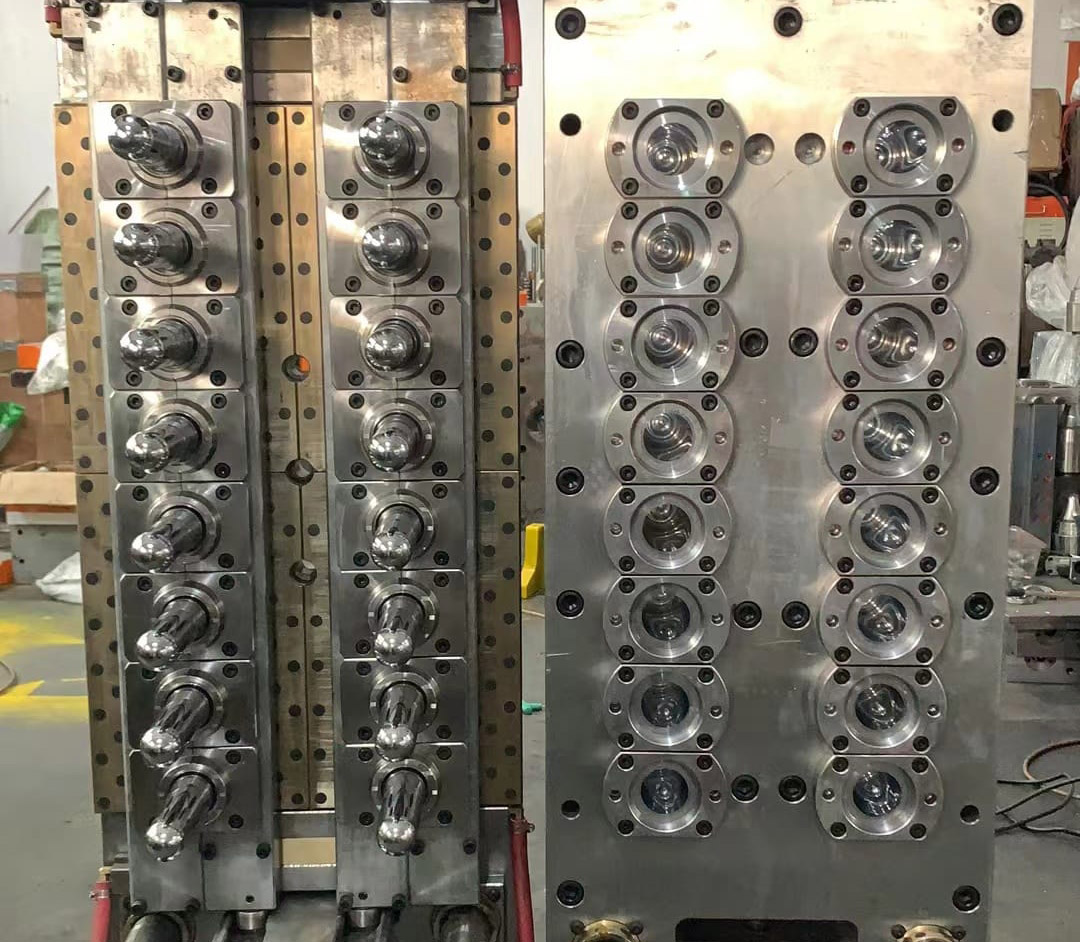

Our mould designed and developed by our engineers, is of high precision

and long life span without traditional problems. In a word, Preform

wall thickness is on error of 0.10mm; Weight difference is less than

0.3G; 2-5 moulds per minute; Utmost 144 cavities in one mould.

Control system with simulating stretch testing improve rate of production.

3.5.

Adopt world advanced dipole taper localization technique, each cavity

self-clamp independently, ensure mould concentrically.

3.6. Material of mould die core and die cavity are made of Sweden special mould steel.

3.7. Standard screw neck, imported nitride steel with high hardness is of long usage.

3.8. Advanced hot runner design and even heating temperature make sure the high quality of plastic products.

3.9. Valve gated type without tail reduces labor force.

3.10. At least 3 million shots guarantee.

4. Electric Heating Components

1. German Hottest heating components.

2. German intelligent temperature controller (PID continuous power controlling).

3. Offering temperature controller and voltage controller according to customers' requirement

5. After-Sales Service

Technologists professional in after-sales line and excellent credit assures stable operation of the machines.