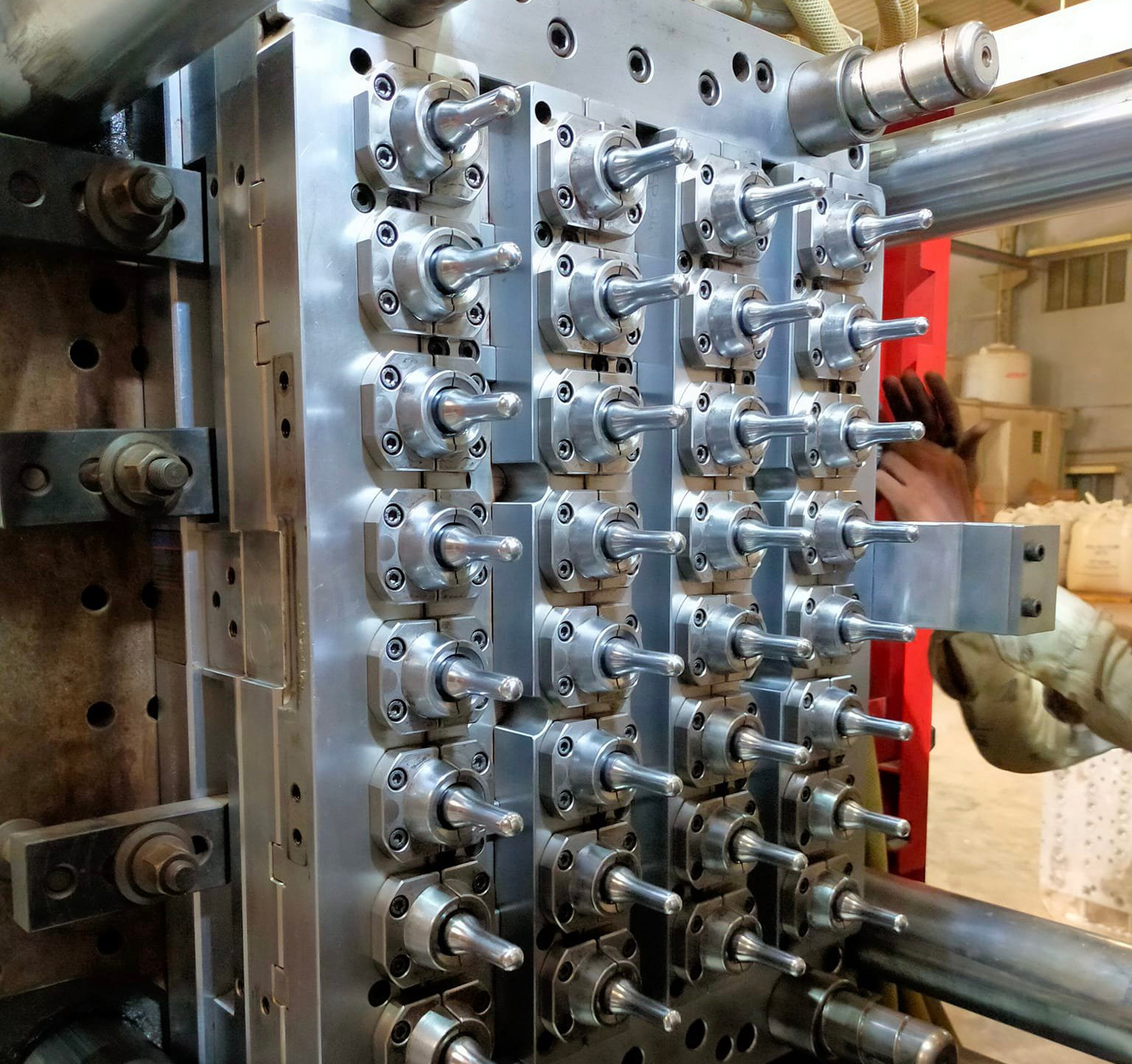

Hot selling good quality 8cavity Hydraulic Self-locking Valve Gate PET Jar preforms Mould, PET Jars Mould, PET bottles Mould, PET packaging Mould, Blowing PET bottles Mold.

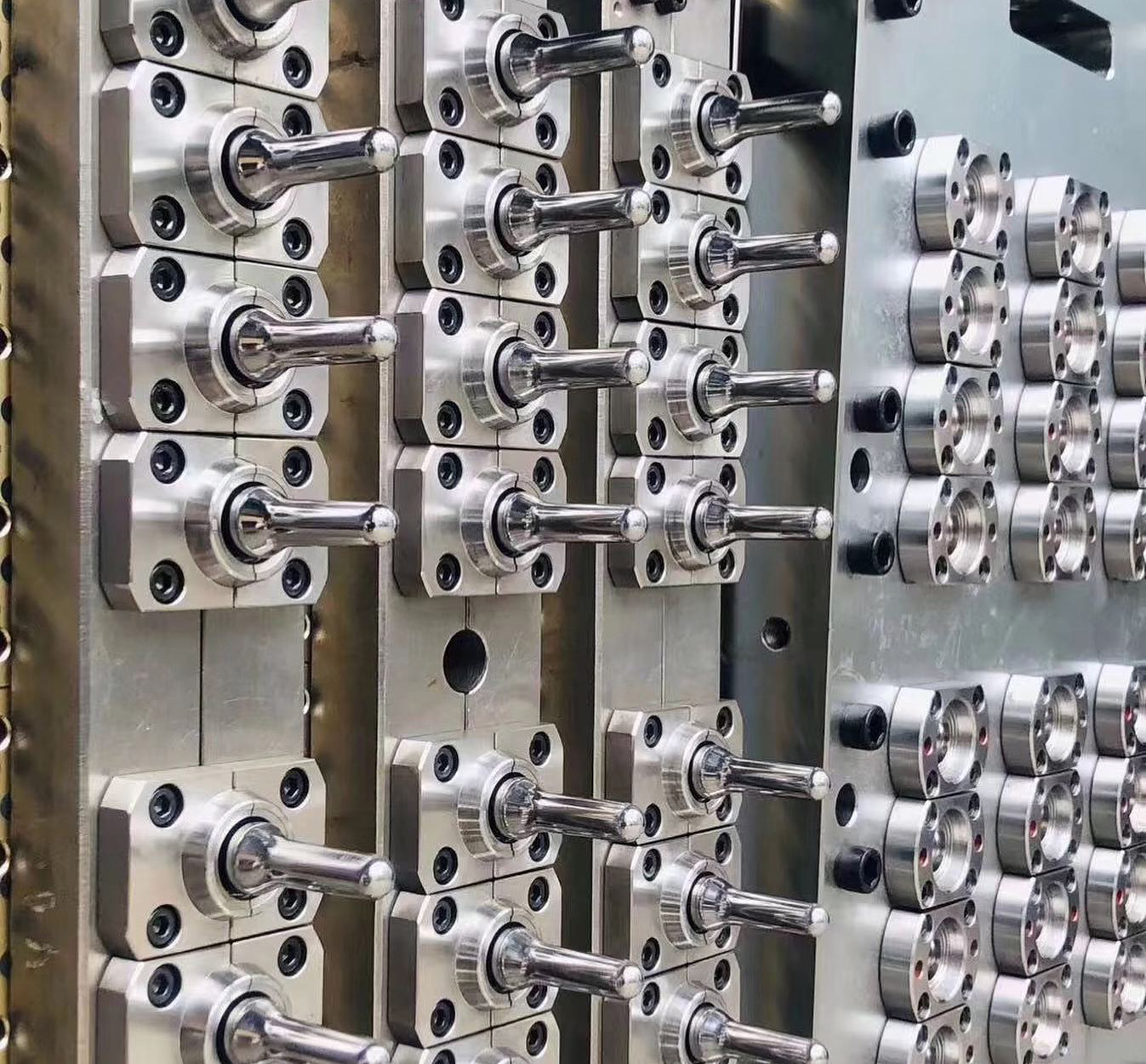

Along with higher and higher demand of perfect forming, more and more considering of energy saving, Nowadays, cold runner system was eliminated in PET Preforms mould making, usually, Multi-cavity PET Preform mould does use the hot runner system, so the design of hot runner system plays an very important role in PET Preform mould quality guarantee. On the base of foreign advanced techniques, our PET Preforms mold adopt the valve gate(shut-off) design, in which each cavity has its own heating zone and temperature is measured by independent thermo couple. So some old traditional problems such as left white marks or drawbench on bottom are easily avoided. Mould is produced automatically to save labor force.

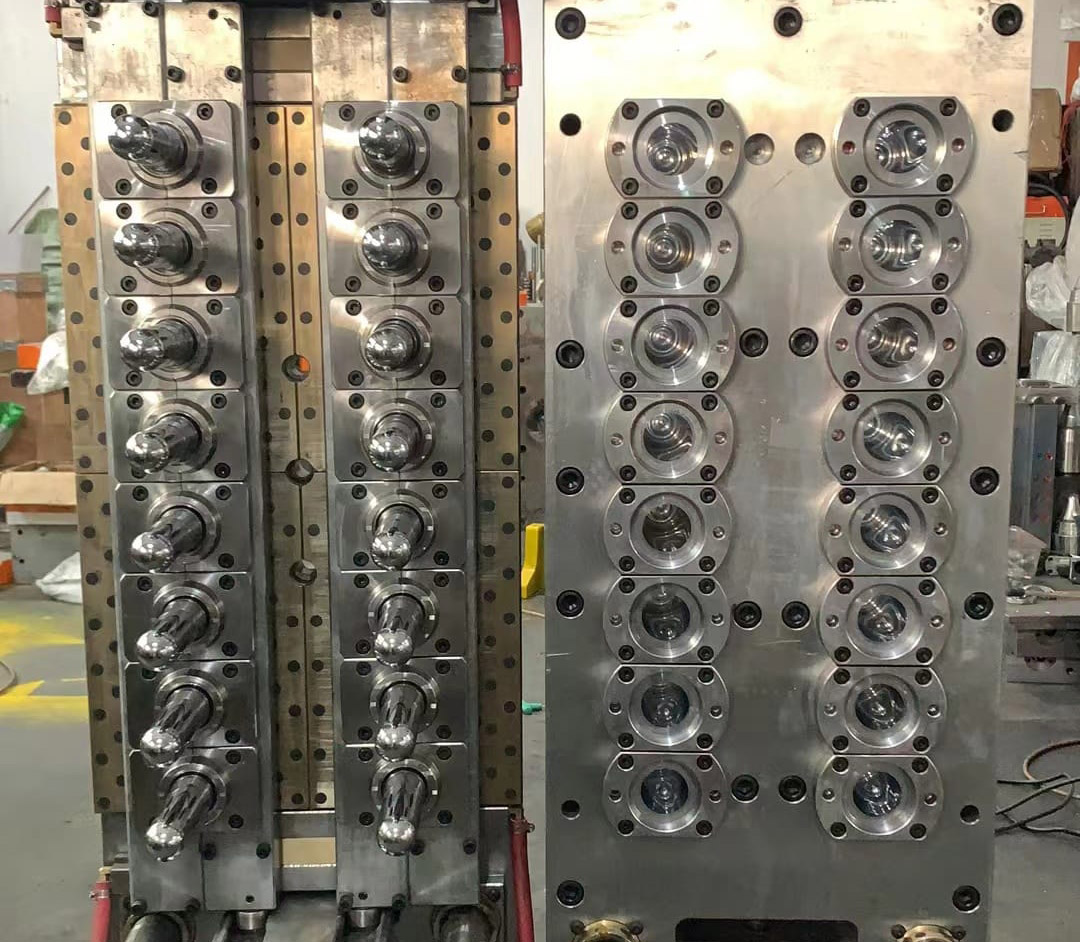

Main mould components (core, cavity, screw neck) are made of high-quality mould steel S136 which originates from Sweden (ASSAB). German Vacuum stove is imported for heat treatment of the components, which assures the hardness of components HRC48-HRC50.

In this way, it is no doubt that the mould can be used for 2 million shots without any maintenance, meanwhile, the wall thickness difference between is not more than 0.10mm (length<=100mm), weight difference is less than 0.3g; turning center processes make sure that every mould parts can match very well to ensure mould concentricity; Proper distribution of cooling water system improve productivity effect and molding cycle only takes 15seconds. Utmost 144 cavities in one mould.

PET Jars Preform Mold material:

1. Core and Cavity: HRC48-50, ASSAB S136 from Sweden

2. Neck screw: HRC48-50, ASSAB S136 from Sweden

3. Nozzle: HRC48-50, Beryllium Copper

4. Nozzle hosts Material: SKD61

5. Insulator Material: DuPont from USA

6. Valve Pin: HRC60-62, Material: SKD 61 Japan

7. Heating Coil and Thermo couple Brand: ROTFIL from ITALY

8. Plastic seals: made in China

9. Graphite copper plate: HRC30-35, Slider plate is made of 718# steel ( Nickel plating)

10. Mould base plate: HRC30-35, P20

Valve Gate PET Preforms Mould specifications:

I. Off-center Adjustment System

Off-center adjustment system can make the tolerance of Jar's wall thickness less than 0.05mm. This system does not affect the lifetime of mold;

II. Self-lock System

International advanced bi-awls fixed orientation self-locked structure has been adopted.

III. Cooling System

All the water Channels in the mold's each inner part, which make the cycle time short enough. And all the cooling channels have been specially treated to prevent them from jam;

IV. Heating System

Double Heating System can ensure that the impact of heating is good and quality control is credible. The Heating Band unit makes nozzles be with invariable temperature. The Heater Unit is used to heat the hot runner plate with long using life and powerful heating capacity.

V. Hot Runner System

The PET Jars perform mold adopt Pin-valve type Hot Runner System, such hot runner system can reduce mold's each part's wear & tear and maintenance cost, and also save 10%~15% electric energy.

VI. Hydraulic Ejecting System

The perform-doffing success ratio has achieved firm endurance and the whole PET Jars ejecting process will become much quieter