How to choose PET bottle embryo mould correctly?

1.Product weight: different weight products have different requirements for hot runner.

2. Plastic raw materials: different plastic raw materials have different processing variables, and those processing variables will affect the selection of hot runner system.

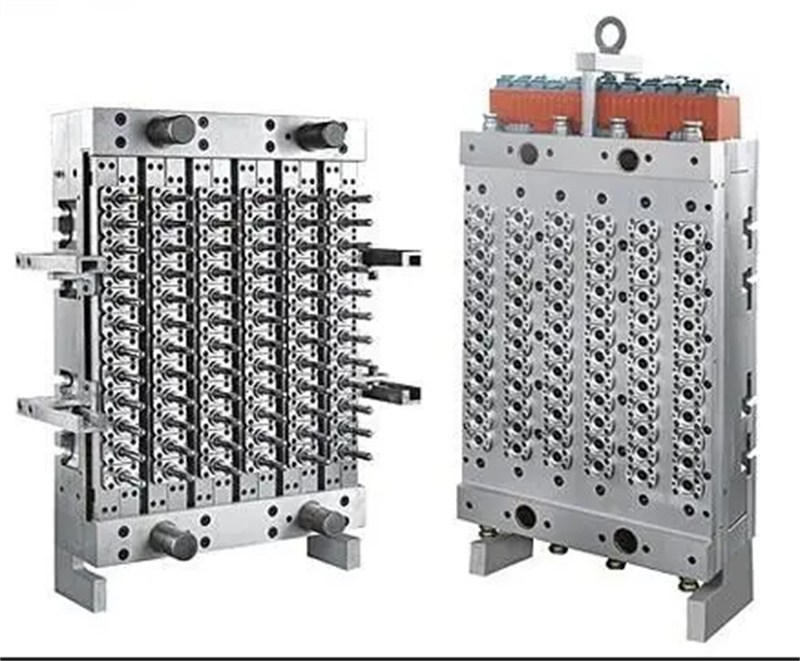

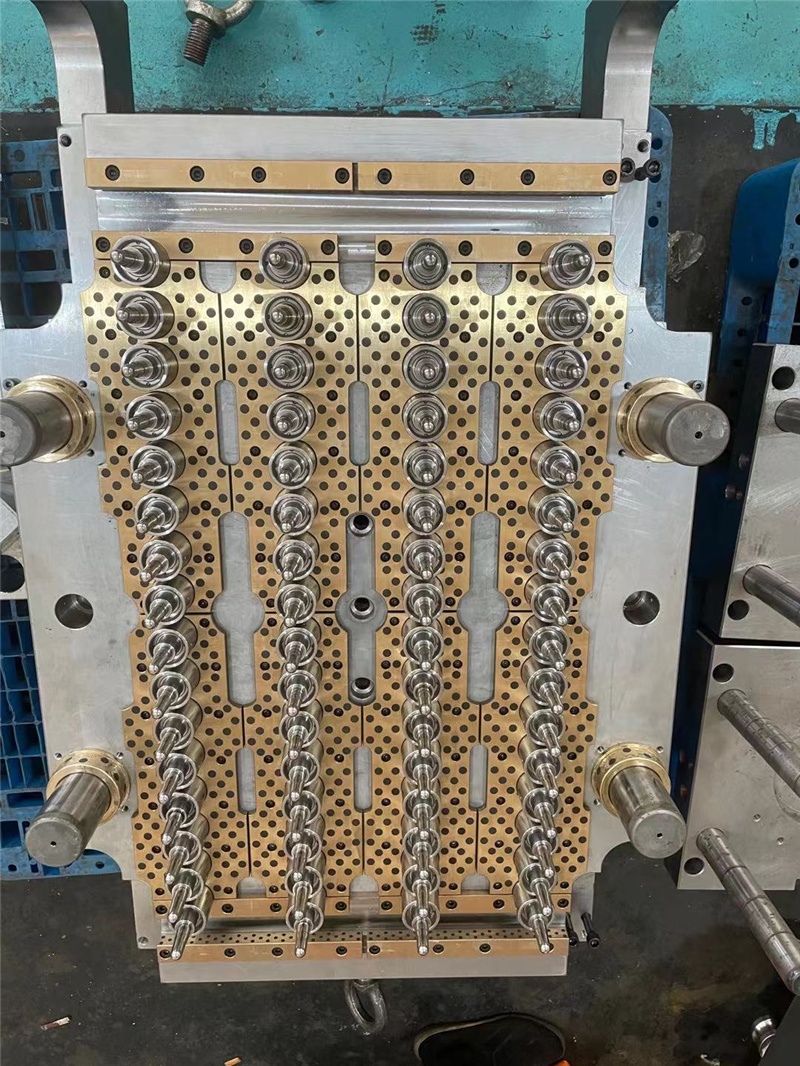

3. Mold: what is the number of image cavities? What is the nozzle distribution distance? What kind of materials are processed? These are mold elements related to the selection of hot runner system.

4. Cycle cycle: fast production cycle means higher requirements for nozzles. For example, the nozzle should accurately transfer heat and be durable.

5. Gate: for point gate, in order to maintain good heat balance in each forming cycle, its heat flow nozzle tip must have the functions of melting materials and cooling sealing. The valve gate adopts mechanical method to seal the gate.

6. Nozzle: the nozzle can generally be distinguished according to size, temperature distribution, physical characteristics, materials used (copper, steel, etc.) and the difficulty and price of maintenance.

7. Runner: the use of hot runner system avoids the generation of material handle, which not only saves raw materials, but also eliminates the previous process of removing material handle by hand, manipulator or other means.

8. Temperature control: each nozzle must be connected to a relatively complex temperature controller.

9. Performance of injection molding machine: it can install molds of given size, provide sufficient clamping force, operate according to the requirements of cycle time, plasticize enough materials, etc.

10. Product design: Generally speaking, we all know that product design is completed first, but the final molding is completed in the hot runner mold. In order to ensure a smooth product appearance at the end of molding and easy to die out, those factors must be considered in the structural design of the product.